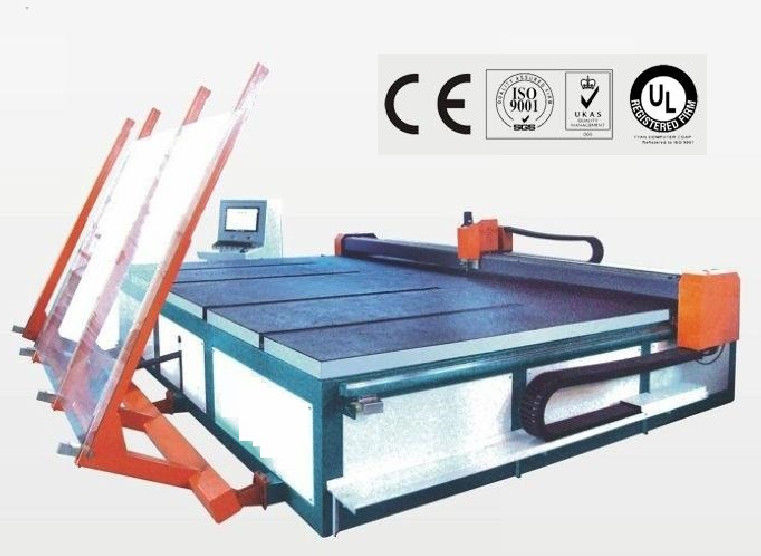

Mosaic Glass Cutter , Glass Cutting Table With Multi – Cutters,Mosaic Glass Cutting Table

| Machine: | Mosaic Glass Cutting&Breaking Machine | Model: | SBT-JQZ-100 |

|---|---|---|---|

| Breaking Speed: | 40pcs/min | Max Size: | 30x30mm |

| Glass Thickness: | 2~6mm | Process Material: | Glass Mosaic/mosaic Glass |

| Transmission: | Belt Driven |

Mosaic Glass Cutting&Breaking Machine

Quick Details

- Machine Type: Glass Cutting Machine

- Place of Origin: China (Mainland)

- Brand Name: SAINT BEST

- Model Number: SBT-JQZ-100

- Certification: CE

- Glass cut: Linear cut

- Cutters: Multi-cutters

- Minimum glass size: 15*15mm

- Maximum glass size:30*30mm

- Glass thickness:2~6mm

Packaging & Delivery

| Packaging Details: | sea-worthy package, wooden crate package |

|---|---|

| Delivery Detail: | 25days |

Specifications

1. Glass breaking machine

2. Mosaic glass break

3. Glass mosaic process

4. Belt transmission

SBT-JQZ-100 Glass Breaking Machine is a continuously glass breaking device for mini-size rectangle and squareness glass ,especially suitable for glasses such as glass mosaic artwork, illumination etc. Besides better quality it also is faster than manual operation 50~60 times.

- Size :10*10~50*50

- Thickness:2~6mm(adjustable)

- Outline dimension: L*W*H 1300*550*1100mm

- Weight :150kg

- operation method

Adjust the distance between 2 iron plates under transmission belt to less than the width of 2 specifications size, and the distance of middle of press wheel and the edge of iron plate is 1 specification size.

The transmission belt will round clockwise after push the push the power on button. Rotate the hand wheel to regulate two bowls space( less than the glass thickness 0.1~0.5mm, the space is according to glass thickness), put the cut glass sheet on the transmission belt with tooth mark above and move forward for trial breaking. Adjust the space between bowls, when the cutting article is satisfactory then the mass production is beginning.

Equipped whit speed adjustable and prograde & reverse electrical machine ,customers can adjust breaking speed according to the thickness of glass .It also can round reversely if necessary.

- Cautions

(1) The glass should move along with ruler( edge line of the ruler should be vertical with bowl line ).

(2) Turn on when adjust speed.

(3) Adjust the handle wheel of bowl shoule be move as equal as possible, make sure the space of two sides are equal or it will affect cutting result.

(4) Please put the machine on a plane and dry position. Don’t move or liberate machine when it is running or it will affect cutting result.

(5) Please be careful when transfer or move .Do not turn over ,Do not put heavy things on the surface of table

(6) Lubricate transmission gear and chain regularly.

(7) Clean the machine in time when cutting work finished.

Machine Processing

SAINT BEST GROUP selected each part carefully , we are strive to quality first when machine production and test each machine before delivery. So we will provide the best machine for you.Automatic Glass Shape Cutting Machine With Semi-Automatic Loading Device,Automatic Glass Shape Cutting Machine,Automatic CNC Shaped Glass Cutting Machine,Shaped Glass Cutting Machine,CNC Shaped Glass Cutting Machine,Automatic Glass Cutting Machine.

Qualit Control

SAINT BEST GROUP engineers have years of experience in window machine fabrication, which makes the precision and stability better than others.

After machine production finished, the products will be tested in professional ways make sure its performance.

Packaging & Shipping

SAINT BEST GROUP produce high quality machines, also pay attention to package.

The machines will be packed with steel pallet and standard export wooden case,

to make sure customer will receive the machines they ordered Intact.

Our Services

Before Sale:

Free contact for the most suitable machine

Free professional design for each customer especially.

After sale service :

24 hours technical support by phone, email or skype (email or skype) .

1years warranty period

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

Payment Terms :

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union or Paypal

A,12month warranty

B,1%-2% spare parts

C, OEM&ODM are welcomed

D,Trail orders are available

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

Saint Best Group always looking for long term cooperaion, not one time deal.

Our Advantage:

Our company owns excellent team of research and development and technician which lay foundation of high-quality machine. We use are imported components and after machine production finished, the products will be tested in professional ways make sure its performance.CNC Glass Cutting Machine,Automatic Glass Loading Machine,Automatic Glass Shape Cutting Line,Automatic CNC Shaped Glass Cutting Line,Shaped Glass Cutting Line,CNC Shaped Glass Cutting Line.CNC Automatic Shaped Glass Cutting Machine with Semi-Automatic Glass Loading

FAQ

1. Question:Are you manufacture?

Answer:

Yes,we are the professional manufacture which have more than 5 workshops.

2.Question: About this Machine,What’s the guarantee ?

Answer:

1).Our guarantee for 12 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).We will provide the consumable parts at an agency price

5).24 hours on line service each day, free technical support.

3.Question:Why your price is higher than another company or factories ?

Answer: please check, what is is the differences of the machine of parts ,service and guarantee,especially the machine inner electric parts,

sometimes,if the machine have breakdown, the most reason is the machine inner electric parts problem,

but we use the famous and reliable parts for the machines inside.